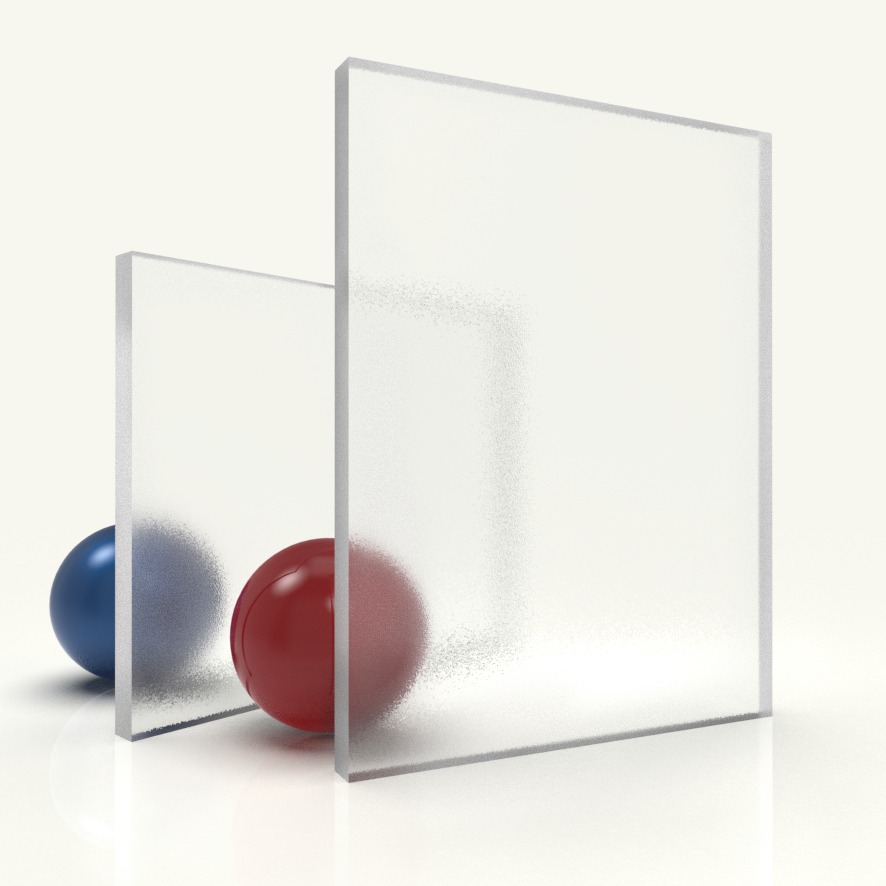

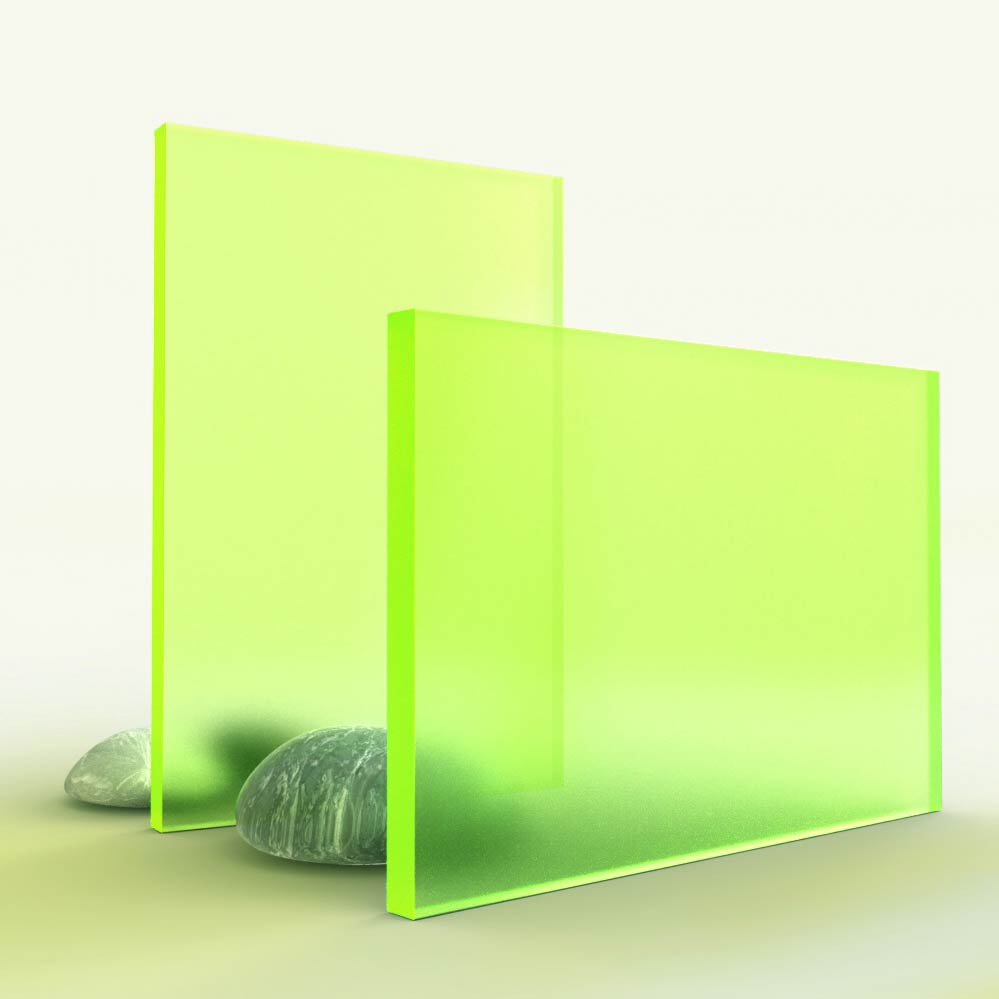

PLEXIGLAS® GS 245

PLEXIGLAS® GS 245 acrylic sheet is suitable and meets the required standards.

The AECMA 4364 and MIL-PRF-5425 are rules that specify how things should be made for airplanes. These rules are important in situations where it is very important to have high standards. These are rules for using in airplanes. It is of high quality and costs more than average.

Making sure that something is smooth and has the right measurements.

Please provide the original text to rewrite it in simple words.

Application means a program or software used on electronic devices like computers, smartphones, and tablets to perform specific tasks or functions.

Current uses of these things include the control panel in a vehicle and the outer end of an airplane wing.

Application

There are things called lenses, dust covers, helicopter bubbles, and aircraft canopies. PLEXIGLAS® GS 245 sheet is a type of material that is used in airplanes and other things that fly in space. See-through containers made of one or more layers. Making something from raw materials, usually in an industrial or manufacturing setting.

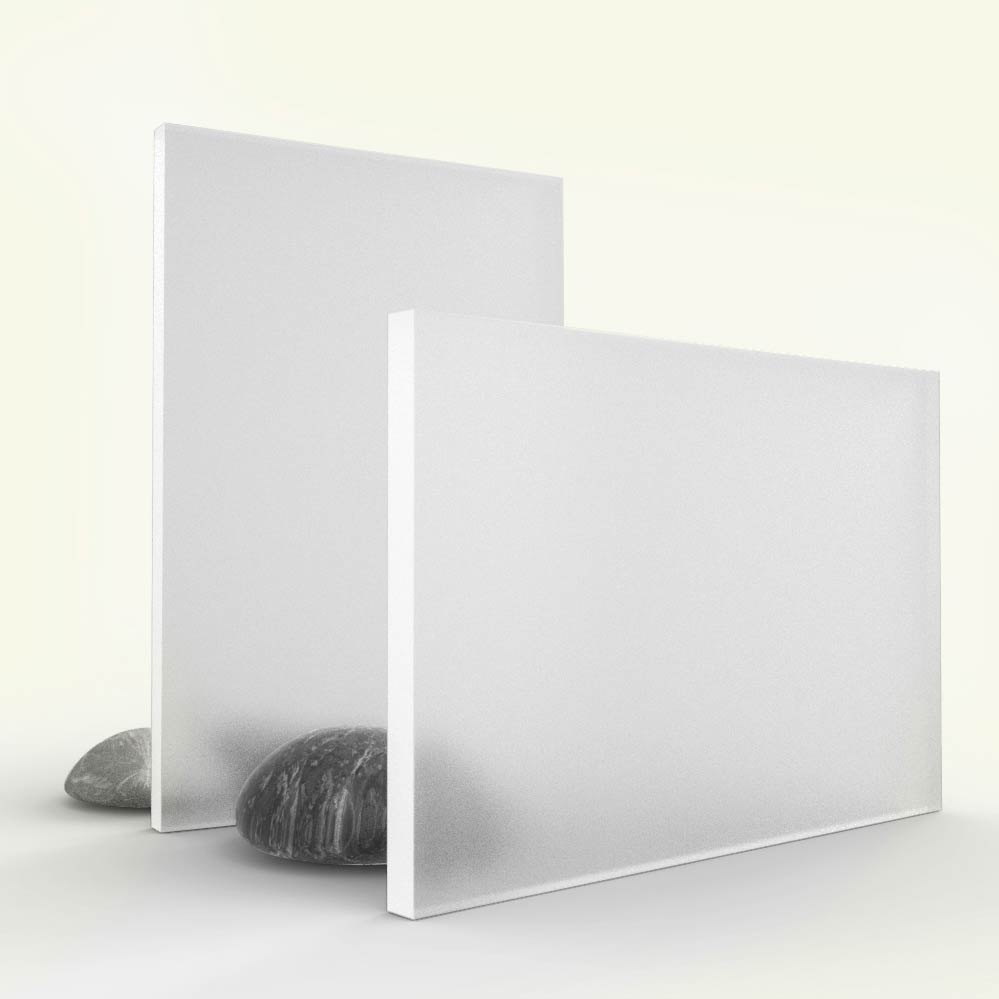

Fabrication

The way we make things out of regular acrylic material. This type of sheet is good for using with PLEXIGLAS® GS 245 sheet. achieved by carefully shaping and draping the material. If you heat up a sheet of material to 150°C all over, you can achieve something. This means the temperature is 160 degrees Celsius. For making shapes by applying pressure or removing air.

It is suggested to use a temperature range from 170 to 190 degrees Celsius.

Properties

The material doesn't let much ultraviolet light through (especially in the range of 290-330 nanometers). This means that something has met certain rules for airplanes and military equipment. It was also approved by the US Navy. This is a type of strong acrylic that can withstand different weather conditions very well. This was made specifically to fulfill the airplane industry's need for excellent optics.

White 7508 - 2.8mm - 48" * 96"

$86.89

White 7508 - 2.8mm - 48" * 96"

$86.89

Green 9093 - 5.5mm - 48" * 96"

$214.00

Green 9093 - 5.5mm - 48" * 96"

$214.00

Orange 2119 - 2.8mm - 48" * 96"

$86.79

Orange 2119 - 2.8mm - 48" * 96"

$86.79

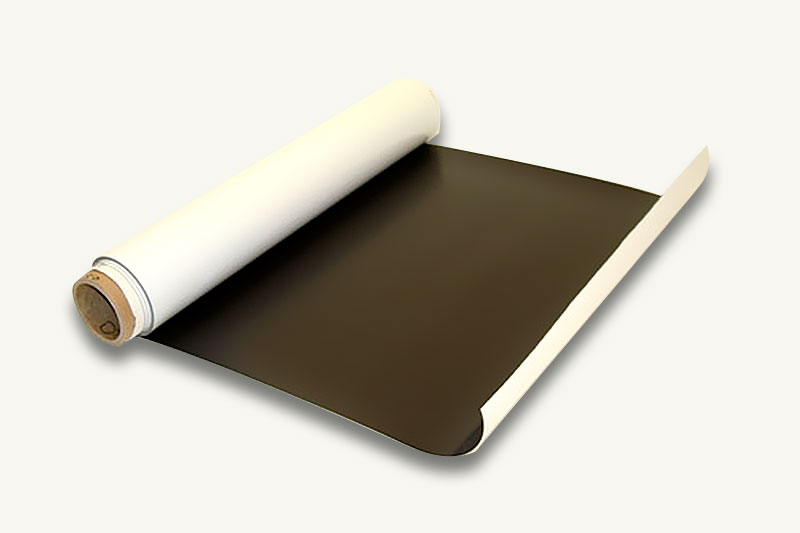

Black 2025M - 2.8mm - 48" * 96" - PS

$369.79

Black 2025M - 2.8mm - 48" * 96" - PS

$369.79